2500mm CNC Bending Machine with ESA S630

| Weight | 950 kg |

|---|---|

| Dimensions | 3200 × 2000 × 2500 mm |

| Capacity |

100T |

| Bending Length |

2500mm |

| Backgauge Axis |

X |

| Controller |

ESA S630 |

| Brand |

HARSLE |

| Price Term |

EXW |

| Lead Time |

30 Days |

| Payment Method |

LC ,T/T |

| Warranty |

Three Years |

10 in stock

2500mm CNC Bending Machine with a crowning system for improved quality, a servo-driven back gauge system for increased speed.

Also has increased working speed, stroke, daylight, and pressing capacities of the machine.

The future – as a result of rising energy costs and increasingly cost-efficient speed-controlled drives offered on the market, variable-speed solutions are in the advance.

Servo 2500mm CNC Bending Machine is fully following European standards, high precision, high security.

Features of 2500mm CNC Bending Machine

1 Direct angle programming with angle compensation function.

2 The grating ruler’s real-time detection feedback correction, full closed-loop control, back gauge, and slider dead gauge positioning accuracy is ±0.02mm.

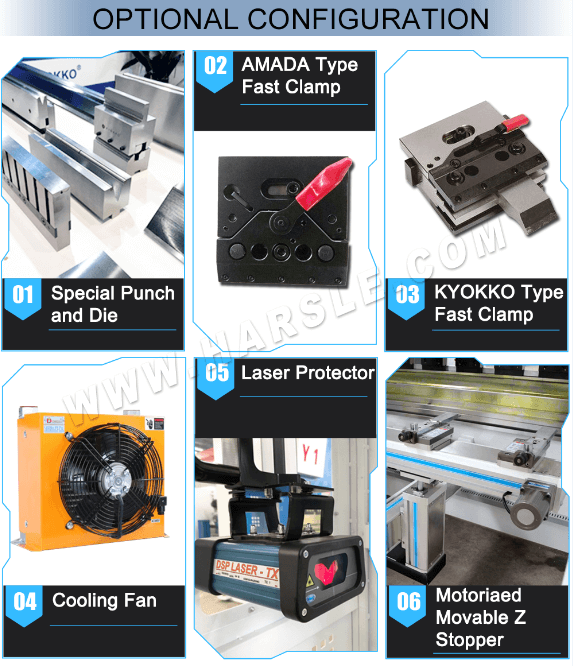

3 The upper mold adopts a quick clamping device, and the lower mold adopts a wedge deformation compensation mechanism.

4 With a multi-step programming function, it can realize multiple automatic operations, complete the one-time processing of multi-step parts, and improve production efficiency.

5 According to user needs, select the imported hydraulic system with stable performance and compact structure, and the back gauge can be driven by a ball screw and timing belt.

2500mm CNC Bending Machine safety standard

EN 12622: 2009 + A1: 2013 /EN ISO 12100: 2010 /EN 60204-1: 2006 + A1: 2009

Front protection device to protect fingers (safety light curtain)

South Korea KACON footswitch (level 4 safety level)

Rear metal protection and CE standards

Safety relay monitor completes pedal switch, safety protection

Safety standard (2006/42/EC)

2500mm CNC Bending Machine Main features

The whole welded machine structure achieves high rigidity; the machine design by ANSYS software can ensure the reliability and precision of the CNC press brake.

WE67K Series CNC press brake is redesigned based on users’ preference to increase productivity and keep the costs at a minimum level with high bending accuracy and low-cost maintenance.

High quality and repetitive bending accuracy is obtained by using a synchronized cylinder and proportional valves

Bending angle calculation and back gauge position calculation can be achieved by inputting metal sheet material information, sheet size, and punch and die size.

The crowning system can work with a CNC controller automatically to achieve higher bending accuracy and linearity. Hydraulic crowning and motorized crowing systems are optional.

CNC back gauge with several axes can work with different shape work-pieces well.

2500mm CNC Bending Machine S630 CNC controller

10” graphic touch screen

Interactive 2d graphics editor

Automatic crowning system control

Automatic bending angle calculation

Bending tool/material/product library

Can Manage up to four axes in any combination

2D graphic display for machine frame, work-piece, and tools

2500mm CNC Bending Machine CNC Axis Explanation

Y1 Left cylinder electro-hydraulic synchronous closed-loop control axis

Y2 Right cylinder electro-hydraulic synchronous closed-loop control axis

X Back gauge moving axis (back and front)

R Back gauge moving axis (up and down)

V CNC crowning axis

Why Choose HARSLE?

HARSLE is a professional metalworking machine manufacturer in China for many years, our productions have been sold to over 100 countries in the world!

Reviews

Clear filtersThere are no reviews yet.