5 Axis CNC Hydraulic Press Brake 125T3200 DA53T

| Weight | 950 kg |

|---|---|

| Dimensions | 3200 × 2000 × 2500 mm |

| Capacity |

125T |

| Bending Length |

3200mm |

| Backgauge Axis |

X+R |

| Controller |

DA-53T |

| Brand |

HARSLE |

| Lead Time |

30 Days |

| Payment Method |

LC ,T/T |

| Price Term |

EXW |

| Warranty |

Three Years |

10 in stock

WE67K-100T/3200 CNC DA53T Press Brake Parameter

Standard Configuration

|

|

| Item | Unit | Value |

| Capacity | KN | 1000 |

| Bending Length | mm | 3200 |

| Opening Height | mm | 420 |

| Cylinder Stroke | mm | 200 |

| Throat Depth | mm | 400 |

| Motor Power | KW | 7.5 |

5 Axis CNC Hydraulic Press Brake uses a servo motor as an actuator, so when the bending operation is not performed, the motor does not move and consume power.

5 Axis CNC Hydraulic Press Brake is a product that meets modern environmental protection and energy-saving requirements.

The servo motor has a higher degree of controllability, so the processing accuracy is higher, and it can well adapt to the production needs of the industry with increasing workpiece accuracy.

5 Axis CNC Hydraulic Press Brake Main features

The whole welded machine structure achieves high rigidity; the machine design by ANSYS software can ensure the reliability and precision of the CNC press brake.

WE67K 5 axis 125T/3200 DA53T CNC hydraulic press brake is redesigned based on users’ preference to increase productivity and keep the costs at a minimum level with high bending accuracy and low-cost maintenance.

High quality and repetitive bending accuracy is obtained by using a synchronized cylinder and proportional valves

Bending angle calculation and back gauge position calculation can be achieved by inputting metal sheet material information, sheet size, and punch and die size.

The crowning system can work with a CNC controller automatically to achieve higher bending accuracy and linearity. Hydraulic crowning and motorized crowing systems are optional.

CNC back gauge with several axes can work with different shape work-pieces well.

Features of 5 Axis CNC Hydraulic Press Brake

1.The frame has good rigidity, high processing precision, good manufacturability, and convenient installation and transportation.

2.The 5 axis 125T/3200 hydraulic press brake adopts the integral slide block and the worktable, the force is more reasonable, and the load is evenly distributed.

3.The electro-hydraulic servo numerical control bending slider is rigidly connected with the oil cylinder, which better guarantees the synchronization accuracy requirements of the slider in the fast forward, work forward and fast return states.

4. Due to the feedback of the grating ruler and the control of the synchronous valve, the machine has strong anti-eccentric load capability.

5 The advanced variable oil pump technology is adopted, which can save a lot of energy consumption (about 50%) and reduce the processing cost.

6. The operation and maintenance are more convenient and the reliability is higher;

7. The operating cost is the single unit price of the dual unit linkage. The efficiency and processing accuracy are higher than that of dual machines.

5 Axis CNC Hydraulic Press Brake safety standard

1. EN 12622: 2009 + A1: 2013

2. EN ISO 12100: 2010

3. EN 60204-1: 2006 + A1: 2009

Front protection device to protect fingers (safety light curtain)

South Korea KACON footswitch (level 4 safety level)

Rear metal protection and CE standards

Safety relay monitor completes pedal switch, safety protection

Safety standard (2006/42/EC)

DA53T CNC controller

“Hot-Key” touch navigation

10.1″ high-resolution colour TFT

Up to 4 axes (Y1, Y2 + 2 aux. axes)

Crowning control

Tool / material / product library

Servo and frequency inverter control

Advanced Y-axis control algorithms for closed-loop as well as open-loop valves

TandemLink (option)

USB memory stick interfacing

Profile-T offline software

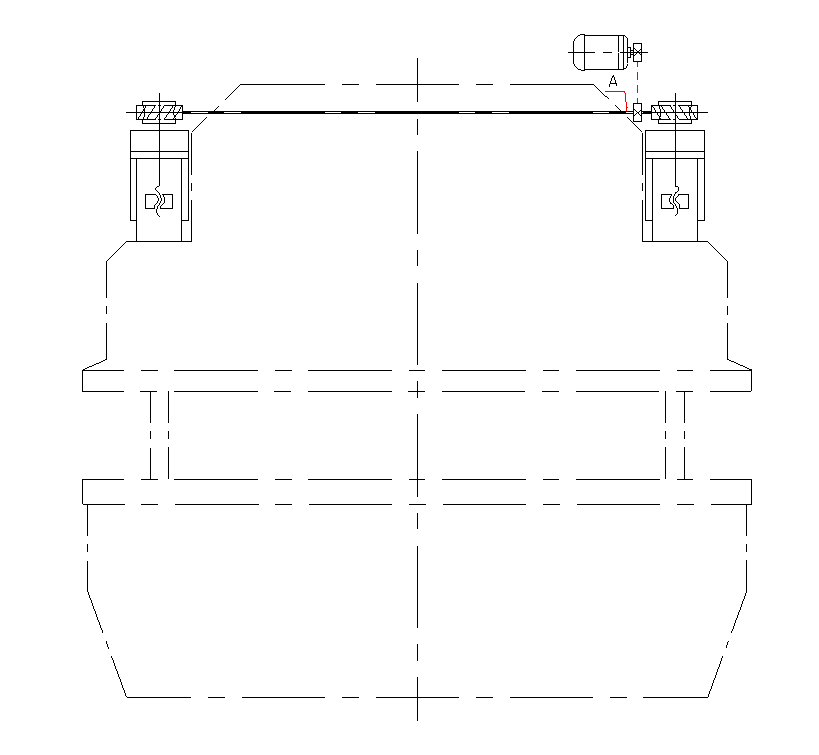

5 Axis CNC Hydraulic Press Brake CNC Axis Explanation

Y1 Left cylinder electro-hydraulic synchronous closed-loop control axis

Y2 Right cylinder electro-hydraulic synchronous closed-loop control axis

X Back gauge moving axis (back and front)

R Back gauge moving axis (up and down) 5 Axis CNC Hydraulic Press Brake

3 reviews for 5 Axis CNC Hydraulic Press Brake 125T3200 DA53T

Clear filtersWhy Choose HARSLE?

HARSLE is a professional metalworking machine manufacturer in China for many years, our productions have been sold to over 100 countries in the world!

Andrey Dronkin –

my sheet is 1500*2500mm , which kind machine is suitable ?

Julian Lopez –

The price is interested me. what is the total cost to Thailand of bangkok port ?

Ivy Zhang –

The machine needs one 40HQ container, I will check the shipping cost , then reply you through email

gabriel prada –

for the 125T/3200 model, how much thickness can bend ?5mm is OK?

Ivy Zhang –

yes, it is Ok if your sheet material is carbon steel